Is predictive maintenance on your radar?

Speak to Alan – Our Product Specialist

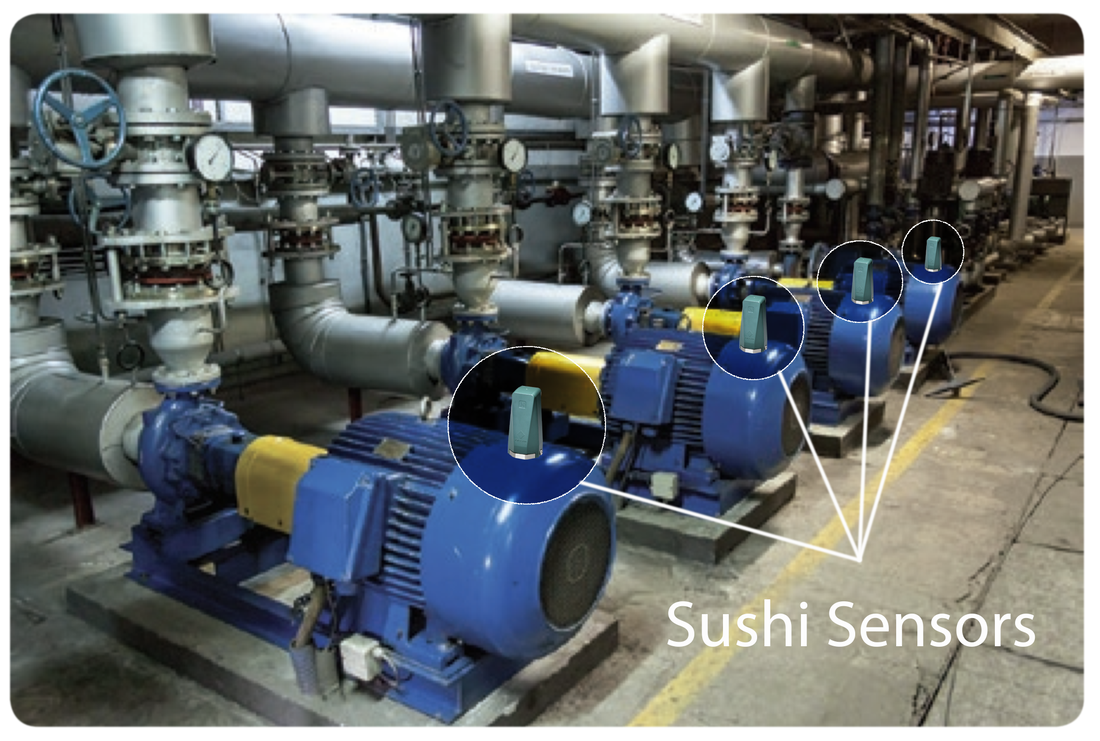

Yokogawa Sushi Sensors

The Yokogawa Wireless Sushi Sensors won Plant Engineering’s ‘Product of the Year’ award to go with the PAM 2020 award for ‘Best Asset Monitoring Technology’.

The Sushi Sensors utilise IIoT wireless technology to provide asset monitoring of critical equipment for preventative maintenance.

Parameters monitored include Vibration, Pressure and Temperature.

These products can prevent costly downtime and equipment repairs while improving safety for process equipment and plant personnel.

- Identifying the status of the entire equipment in plant and visualizing its soundness

- Monitoring the trends and precisely identifying signs of abnormality

- Accumulating digital data of instruments and optimizing equipment maintenance plans

Expert Product Support

Irish Power & Process’ extensive experience in the pharmaceutical and medical device industries aligns perfectly with Yokogawa’s precision-engineered products. A standout offering from this partnership is Yokogawa’s innovative Sushi Sensor. This industrial IoT wireless solution provides long-range communication for monitoring critical parameters such as pressure, temperature, and vibration. The Sushi Sensor’s compact, battery-powered design and its ability to withstand harsh environments make it ideal for Irish industrial settings. By leveraging Yokogawa’s advanced technology and IPP’s local expertise, Irish engineers gain access to world-class instrumentation and calibration tools. This synergy ensures that Irish industries can maintain the highest standards of accuracy and efficiency in their operations.

For more information on Yokogawa Sushi Sensors, click here.

We’d love to hear from you.